Which containers are suitable for Owl Eye Monitoring?

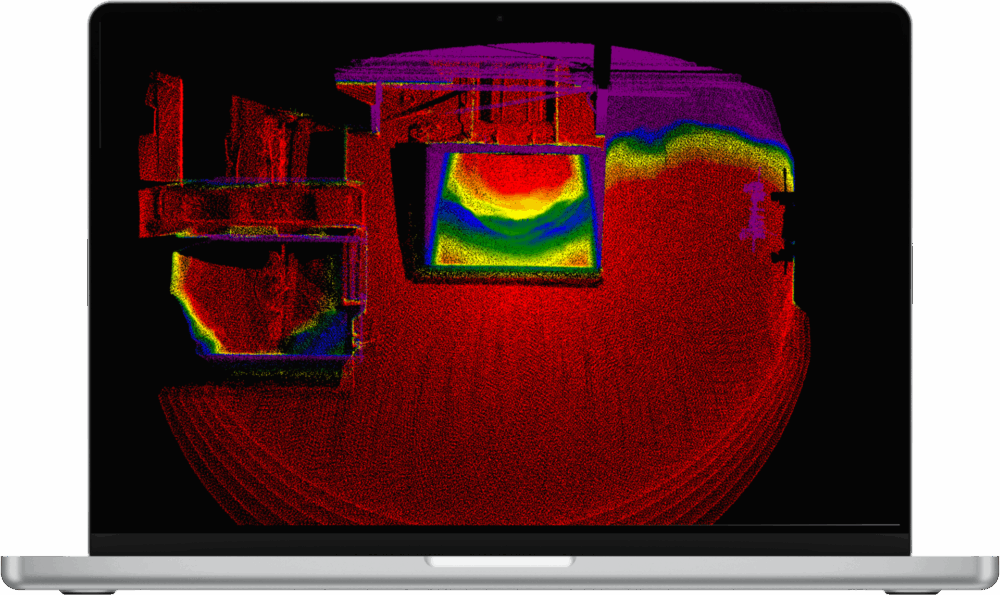

The Owl Eye Monitoring solution offers reliable, intelligent level detection for a wide range of industrial container types. The sensor technology can be flexibly integrated into existing systems and is suitable for both static storage containers and dynamic processes.

Compatible container types at a glance

Our technology was developed for robust use in industrial environments. The following container types are particularly suitable for use with Owl Eye:

-

Silos

Suitable for dry bulk materials such as pellets, granulates or grain. The sensor system works reliably as long as the visibility inside the silo is not permanently impaired.

-

Feed hopper

Particularly suitable for continuous feeding with variable filling height. Owl Eye enables precise detection of the material level.

-

Process container

Data can also be recorded stably and in real time in processes with temperature changes or material movements.

-

Moving floor systems

The sensor system recognises residual quantities and material movements even with uneven emptying.

Restriction for extremely dusty silos

When filling some silos, very high levels of dust can occur for a short time – especially with fine or dry materials. If there is so much dust in the air during this process that even the human eye can no longer see, the use of optical sensors is not suitable.

In such cases, an alternative sensor technology may be required. We will be happy to advise you on the optimum solution for your application.

Conclusion

Owl Eye is a practical and powerful monitoring solution for most industrial container types. In exceptional cases, such as highly dusty silo systems, we will work with you to examine suitable alternatives or additions to the optical sensor system.

Contact us for customised advice on your container type and application scenario.