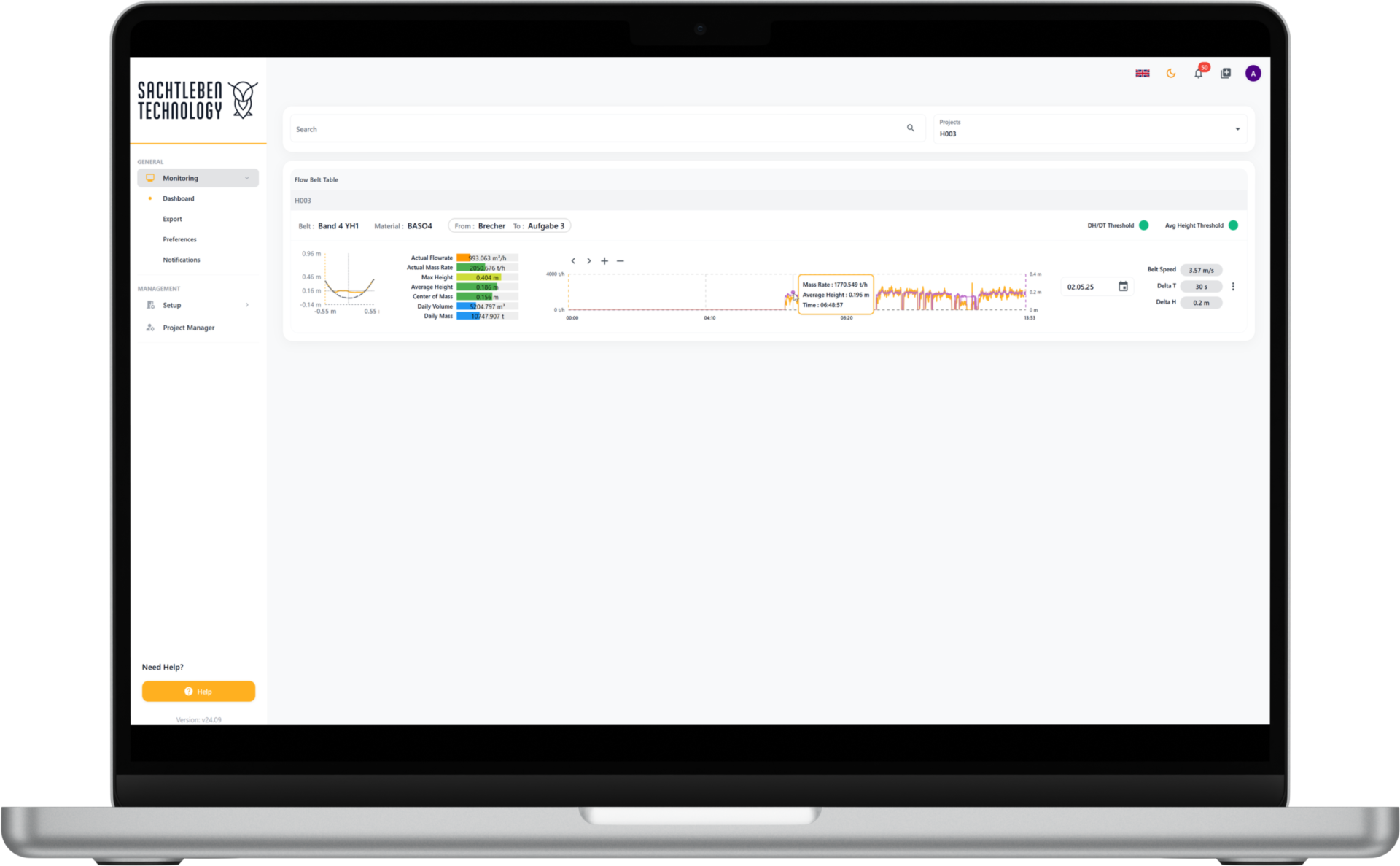

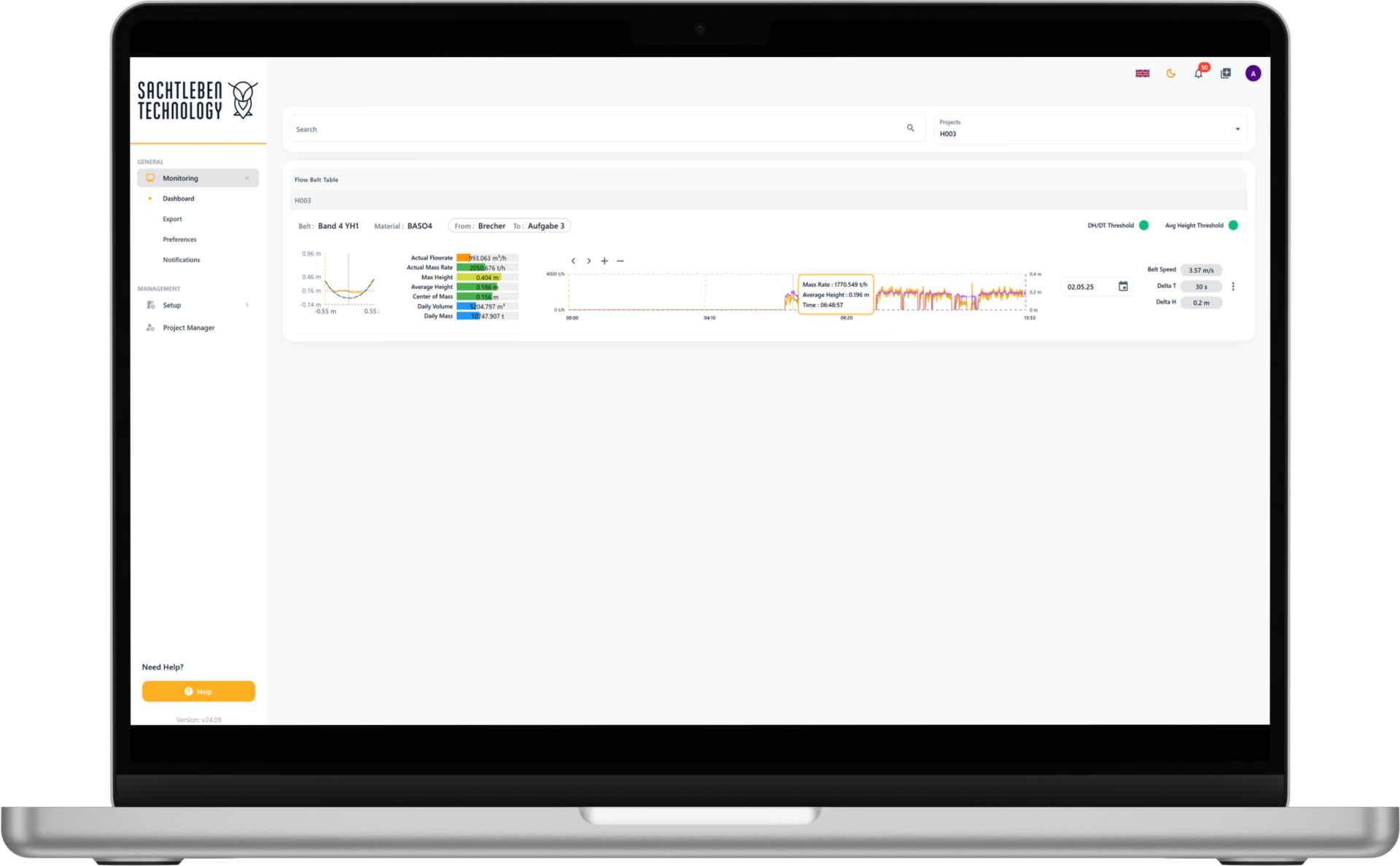

The OWL EYE® volume flow module enables the non-contact detection of volume or mass flows on conveyor belts in m³/h or t/h – combined with intelligent monitoring of the “health status” of the belt.

The system works with a 2D LiDAR sensor that is installed above the conveyor belt. It continuously scans the conveyed goods in a transverse direction and calculates the current throughput based on the belt speed – contactless, precise and low-maintenance.

The non-contact technology means that there are no mechanical wearing parts, making the system particularly maintenance-friendly and durable. Installation is usually completed within a few hours: the system only requires power and a network connection.

In addition to volume or mass flow measurement, OWL EYE® also monitors the condition of the conveyor belt itself – such as uneven material application, belt tracking deviations or anomalies in loading. This enables early maintenance measures and prevents unplanned downtimes.

OWL EYE® can be integrated into existing control centres, MES or ERP systems via OPC UA or REST API.