Owl Eye® conveyor belt bunker: Quantity detection in the feed bunker

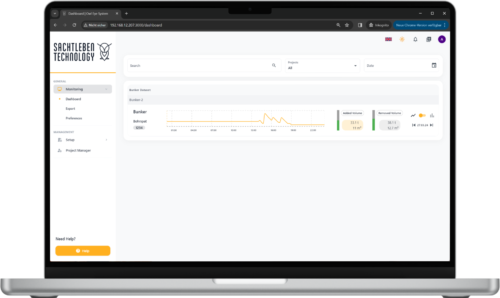

Owl Eye® conveyor bunker system: Dashboard or control station!

The Owl Eye® conveyor bunker system offers versatile and user-friendly data access options to meet the different needs of users. On the one hand, the intuitive dashboard enables simple and clear visualization of the recorded data, giving users a quick and effective insight into the current operating status. The system also offers integration via an OPC UA interface, which allows seamless integration into existing control center systems. This ensures a high level of compatibility and enables the data to be integrated directly into the operational process.

How does the feed bunker measuring system work?

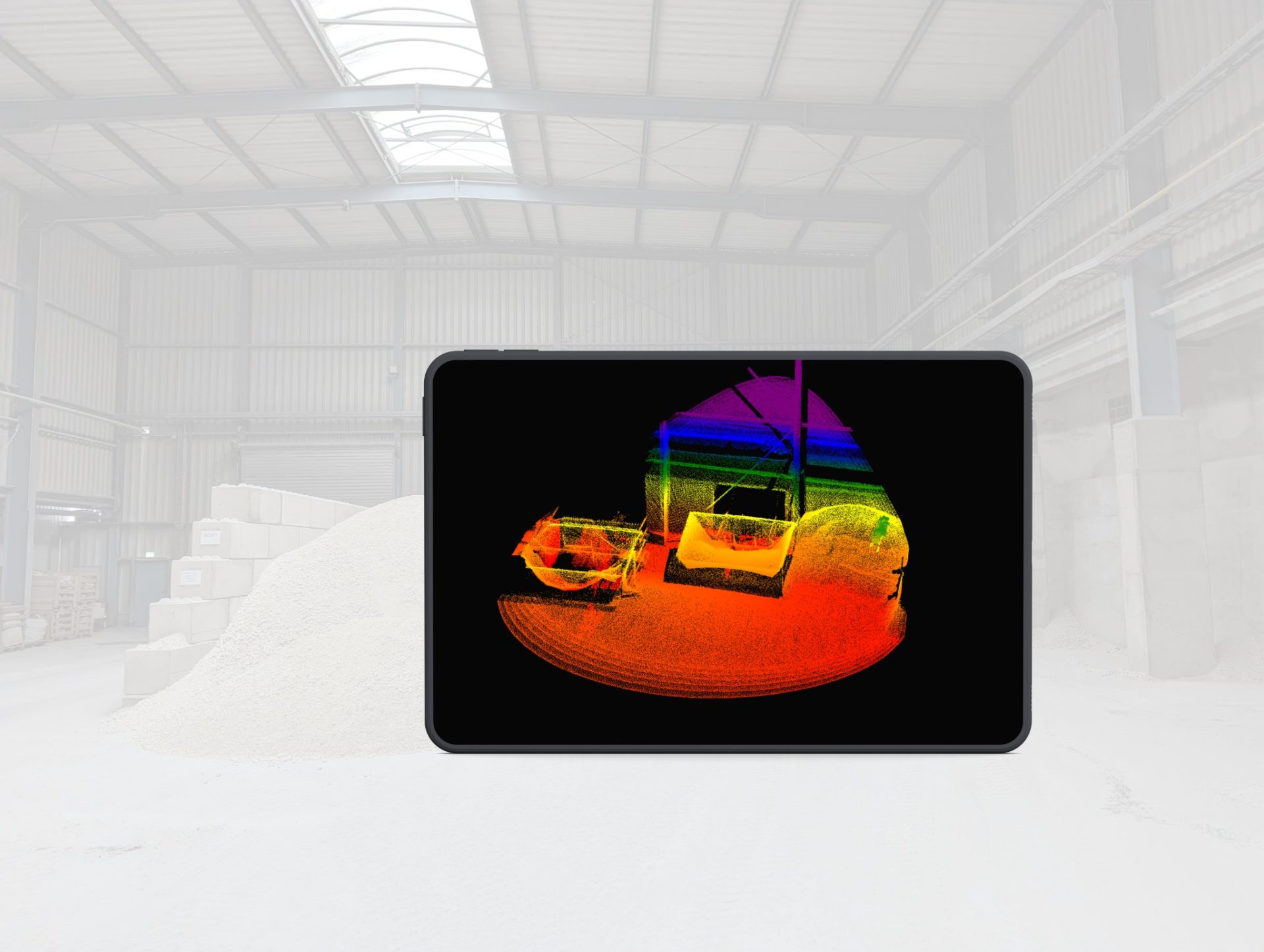

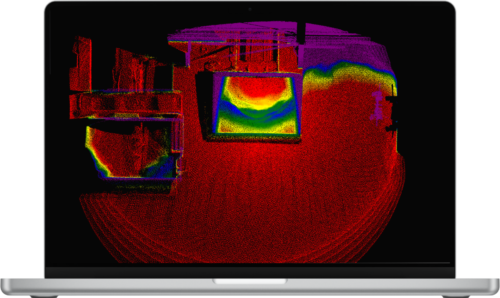

The functional principle of the Owl Eye® conveyor belt bunker measuring system is based on precise LiDAR technology. For implementation, an Owl Eye® LiDAR sensor is installed above the opening of the conveyor belt bunker (for example, on the ceiling above the bunker). Once configured, this sensor begins to scan the contents of the feed bunker in real time. The LiDAR sensor scans the surface of the bunker with high accuracy to capture a detailed image of the material volume. It is interesting to note that the shape of the empty bunker is irrelevant for the functioning of the system; a one-off initialization during commissioning is sufficient.

Intuitive dashboard access options:

Intuitive dashboard access options: