Volume measurement of bulk material with LiDAR

OWL EYE® – MONITORING

The Owl Eye Monitoring System is a system for permanent and precise volume measurement of bulk materials for continuous inventory. High-precision LiDAR sensors are installed in your storage facilities and survey your bulk material in 3D. The Owl Eye is a complete package for fully automated inventory of bulk stockpiles of any size. The data is recorded on a time-controlled basis and stored in an integrated database. Third-party systems such as SAP can control the Owl Eye and access the data at any time.

Stockpile Monitoring System

The network of LiDAR (Light Detection And Ranging) sensors enables high-precision, minute-by-minute time-controlled monitoring of your bulk material inventory according to individual schedules or on demand. With the use of high-end LiDAR sensors, we rely on proven and innovative laser technology, which makes it possible to take into account the smallest details during inventory recording.

Improvement

Guesses and counts lead to an inaccurate inventory evaluation. False estimations are extended from the cradle to the grave. Our fully automated Stockpile Monitoring System helps you to keep continuous track of your inventory.

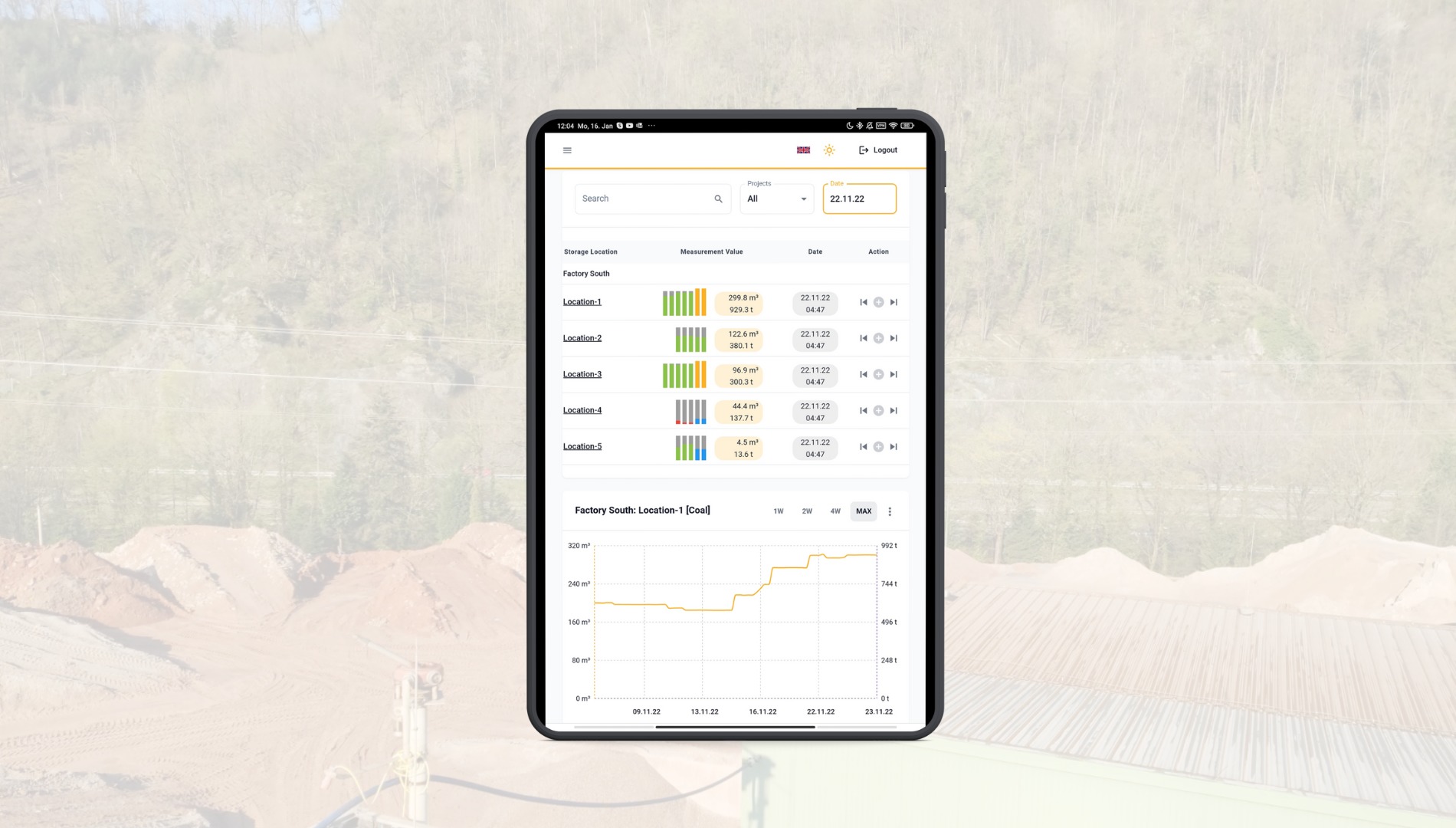

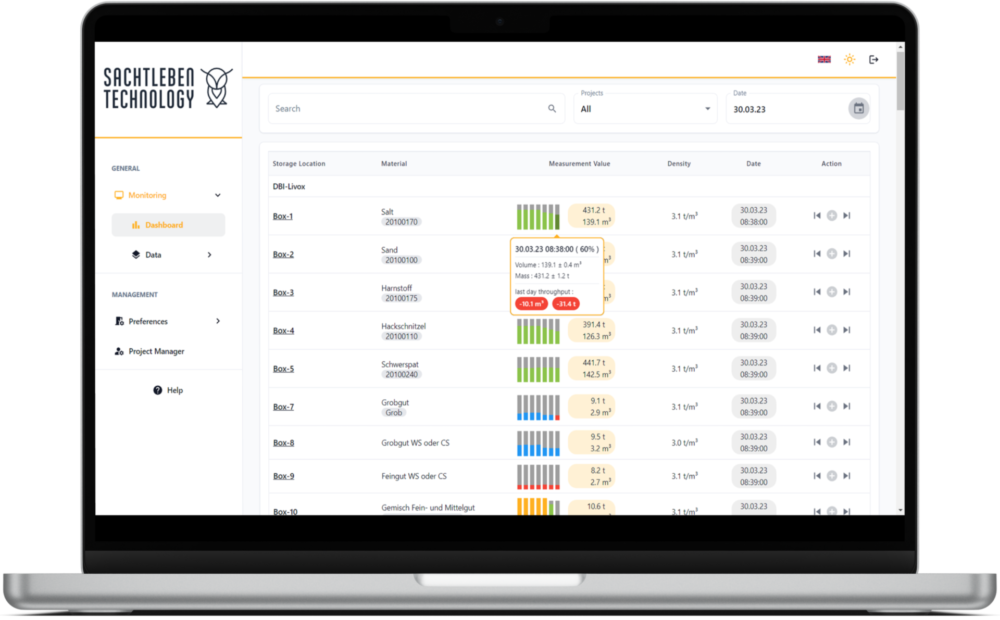

The dashboard offers an efficient solution for monitoring stock levels by combining a clear table with an integrated bar chart. This table provides a quick overview of the current stock of the storage boxes, while the embedded bar chart visualizes the changes in stock over the last seven days at a glance.

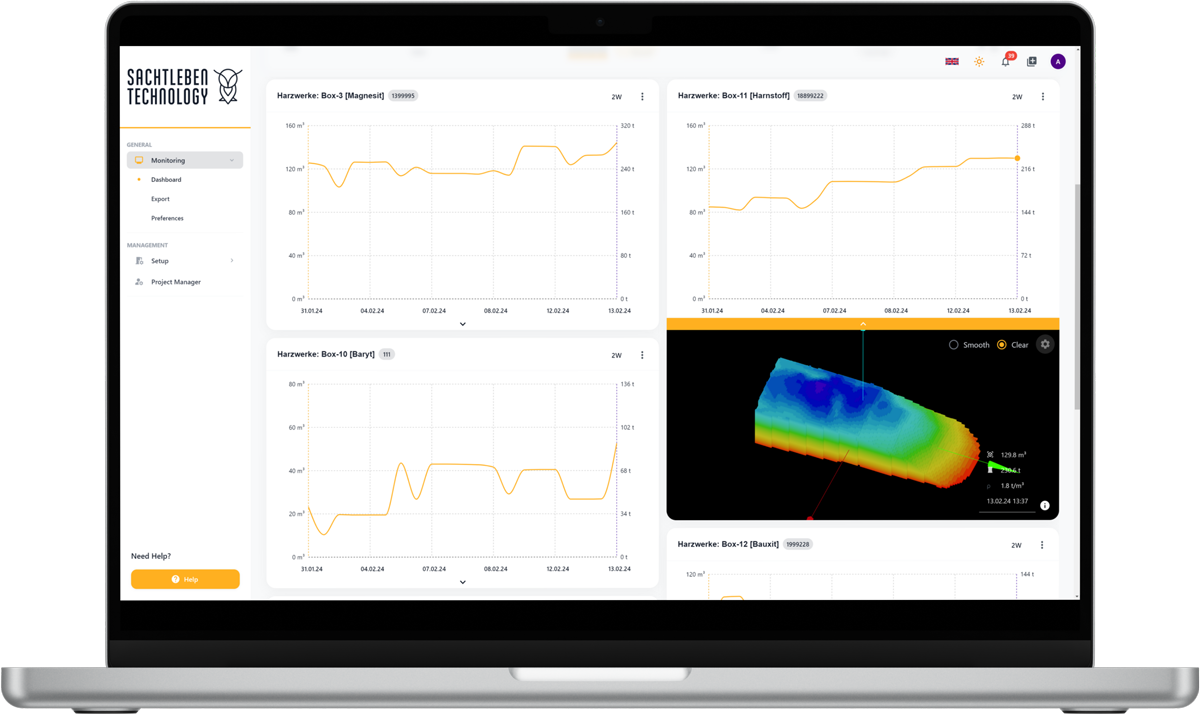

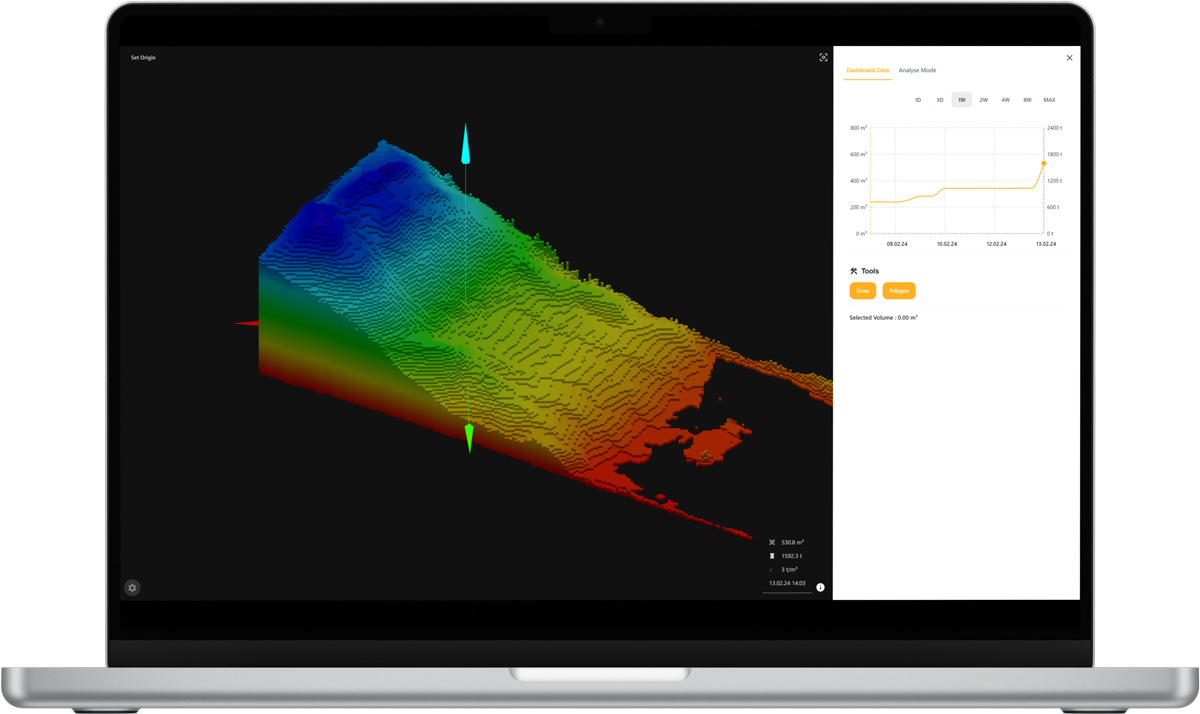

The dashboard offers an efficient solution for monitoring stock levels by combining a clear table with an integrated bar chart. This table provides a quick overview of the current stock of the storage boxes, while the embedded bar chart visualizes the changes in stock over the last seven days at a glance. The warehouse management dashboard enhances inventory analysis by providing a 2D diagram per storage box for visual and detailed analysis. In addition to the graphical representation of quantities over time, it serves as a basis for further analysis. In addition, 3D models of the stored goods are stored for each measured value, providing insights into the shape and stock development so that users can visually track quantitative and physical changes in stock.

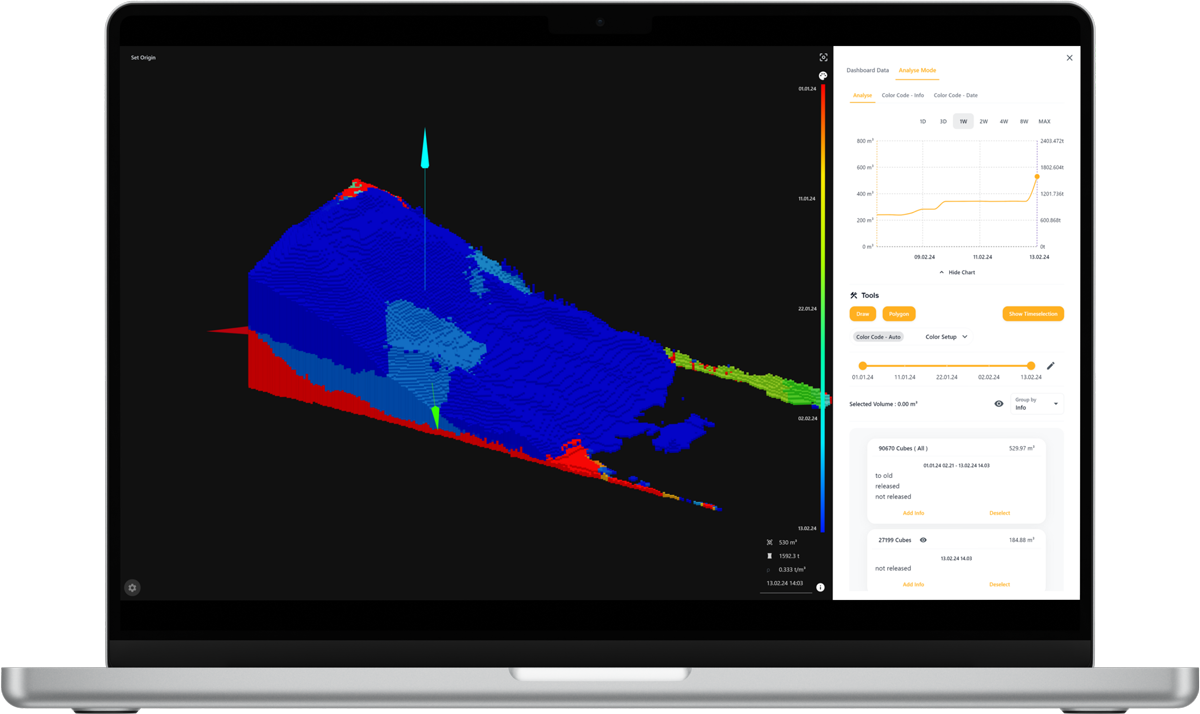

The warehouse management dashboard enhances inventory analysis by providing a 2D diagram per storage box for visual and detailed analysis. In addition to the graphical representation of quantities over time, it serves as a basis for further analysis. In addition, 3D models of the stored goods are stored for each measured value, providing insights into the shape and stock development so that users can visually track quantitative and physical changes in stock. The analysis module enables a detailed examination of individual stockpiles by allowing users to mark specific areas and precisely determine the volume of these selected areas. This functionality extends the data view of the dashboard with the option of carrying out in-depth analyses. Users can thus not only monitor the general stockpile development, but also gain specific insights into the physical condition and changes within individual stockpiles.

The analysis module enables a detailed examination of individual stockpiles by allowing users to mark specific areas and precisely determine the volume of these selected areas. This functionality extends the data view of the dashboard with the option of carrying out in-depth analyses. Users can thus not only monitor the general stockpile development, but also gain specific insights into the physical condition and changes within individual stockpiles.

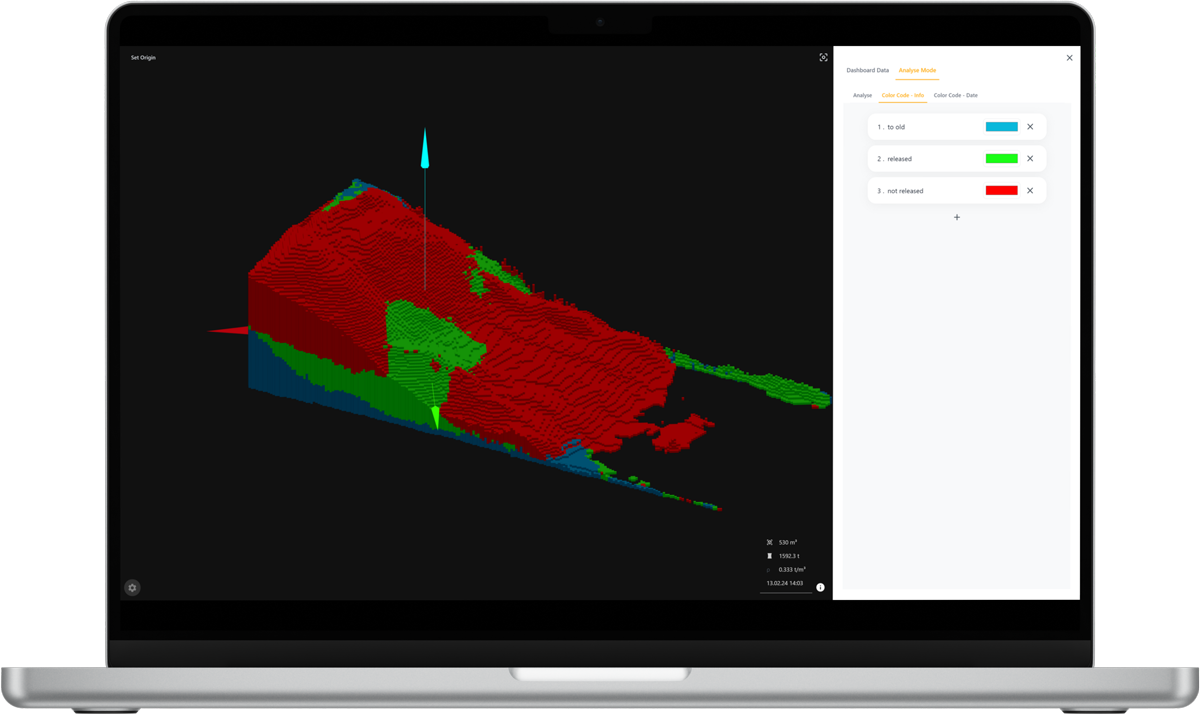

The warehouse management system offers a comprehensive platform for detailed analysis and visual processing of material stockpiles based on a variety of criteria such as laboratory approvals, quality classes or the respective suppliers. This allows users to assign individual data to each material stock and to create a clear and easy-to-understand visualization through color coding. Users have the option of not only recording the specific properties of each stored item, but also visualizing its quantity on the basis of selected characteristics.

The warehouse management system offers a comprehensive platform for detailed analysis and visual processing of material stockpiles based on a variety of criteria such as laboratory approvals, quality classes or the respective suppliers. This allows users to assign individual data to each material stock and to create a clear and easy-to-understand visualization through color coding. Users have the option of not only recording the specific properties of each stored item, but also visualizing its quantity on the basis of selected characteristics. The multi-sensor capable Owl Eye Monitoring System watches over the stock in your warehouses like with the eyes of an owl. Many individual LiDAR sensors are installed as owl eyes in the storage area and combined to form one large eye. The system is very flexible, which means that projects with over 50 sensors in one image do not present any technical difficulties for the system.

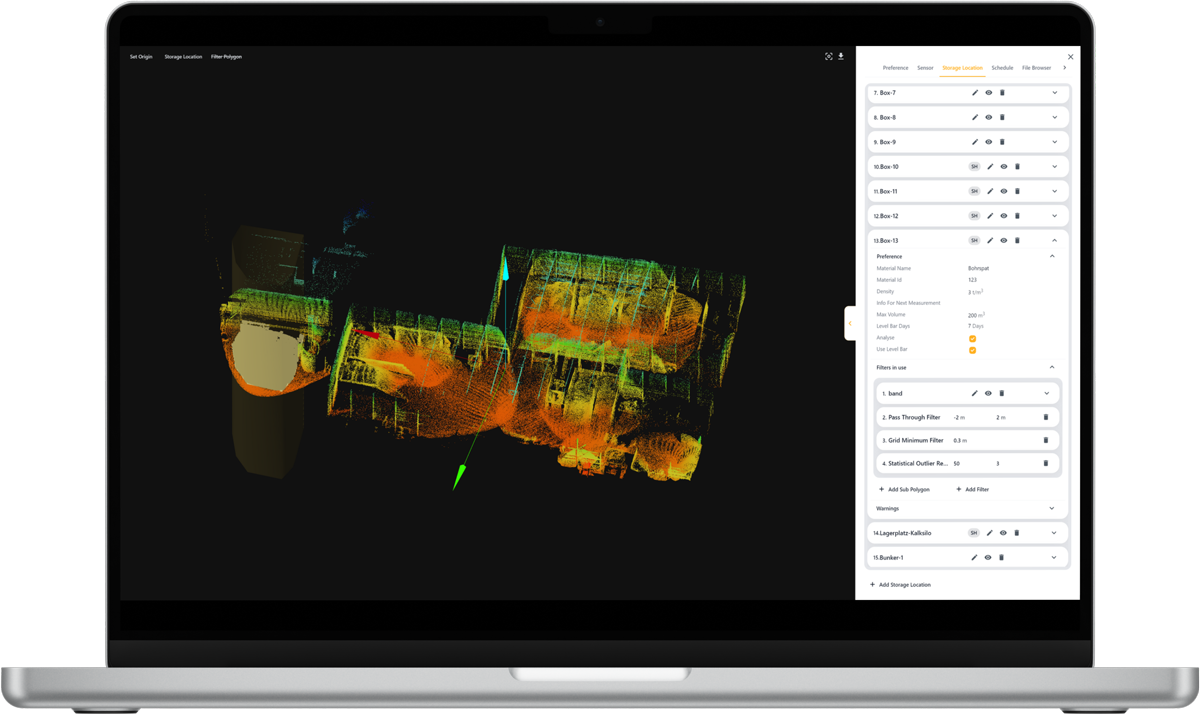

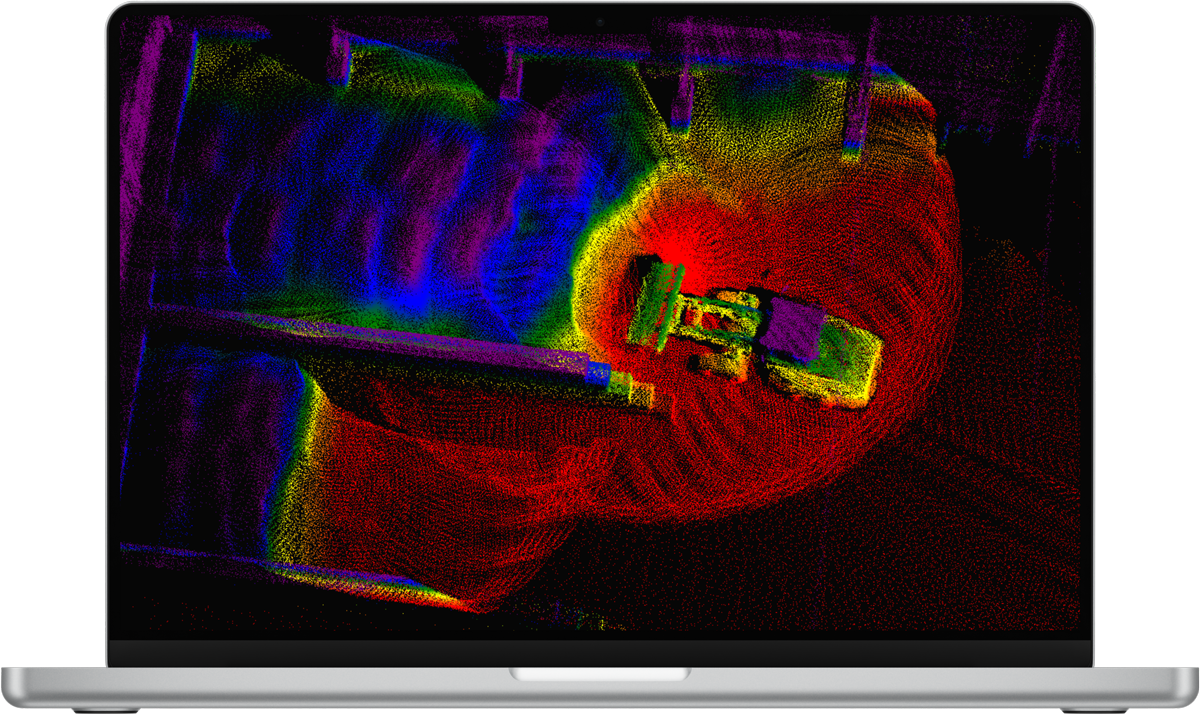

The multi-sensor capable Owl Eye Monitoring System watches over the stock in your warehouses like with the eyes of an owl. Many individual LiDAR sensors are installed as owl eyes in the storage area and combined to form one large eye. The system is very flexible, which means that projects with over 50 sensors in one image do not present any technical difficulties for the system. In this representation of the Owl Eye, two storage boxes and a wheel loader are recorded in a live point cloud video. This 3D data is the basis for the entire system. This gives users a precise and dynamic view of stock levels in real time. Visualization using point clouds enables detailed and interactive exploration of the warehouse environment, significantly increasing the efficiency and accuracy of inventory management.

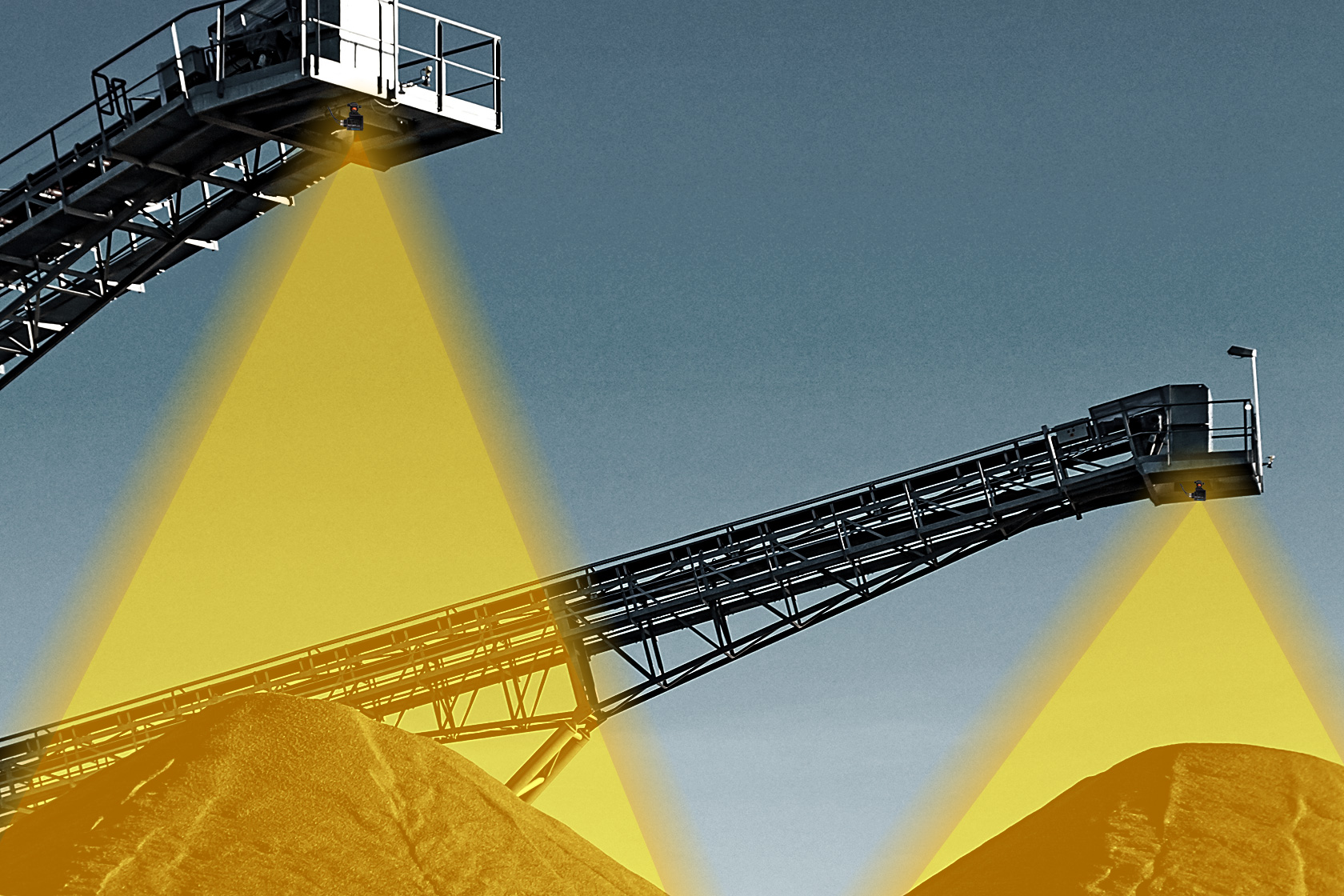

In this representation of the Owl Eye, two storage boxes and a wheel loader are recorded in a live point cloud video. This 3D data is the basis for the entire system. This gives users a precise and dynamic view of stock levels in real time. Visualization using point clouds enables detailed and interactive exploration of the warehouse environment, significantly increasing the efficiency and accuracy of inventory management. Our sensors are typically installed in the ceiling area or generally in raised positions to ensure optimum coverage. Depending on the application and sensor type, the operating range of the sensors varies between 5 and 200 meters, which enables flexible adaptation to a wide range of environments.

Our sensors are typically installed in the ceiling area or generally in raised positions to ensure optimum coverage. Depending on the application and sensor type, the operating range of the sensors varies between 5 and 200 meters, which enables flexible adaptation to a wide range of environments. Our system is manufacturer-independent and integrates various sensors to utilize their specific strengths. This flexibility enables precise environmental detection through data fusion and gives customers access to the latest sensor technologies without being tied to one manufacturer. This enables us to develop customized solutions based on individual customer requirements.

Our system is manufacturer-independent and integrates various sensors to utilize their specific strengths. This flexibility enables precise environmental detection through data fusion and gives customers access to the latest sensor technologies without being tied to one manufacturer. This enables us to develop customized solutions based on individual customer requirements. We also offer the Owl Eye system as a turnkey solution to guarantee our customers a comprehensive and ready-to-use service. Our technicians, who are strategically distributed across three locations in Germany, are also ready to install the Owl Eye system in even the most remote places on the planet.

We also offer the Owl Eye system as a turnkey solution to guarantee our customers a comprehensive and ready-to-use service. Our technicians, who are strategically distributed across three locations in Germany, are also ready to install the Owl Eye system in even the most remote places on the planet. The Owl Eye platform revolutionizes the maintenance and cleaning of sensor units with an innovative, smart cleaning system based on compressed air blow-off. This advanced method makes it possible to efficiently and automatically remove dust and dirt from the sensor lens without physical contact or the use of cleaning agents. The underlying software plays a crucial role here: it continuously monitors the condition of the lens and automatically activates the compressed air valve as required to ensure optimum cleaning.

The Owl Eye platform revolutionizes the maintenance and cleaning of sensor units with an innovative, smart cleaning system based on compressed air blow-off. This advanced method makes it possible to efficiently and automatically remove dust and dirt from the sensor lens without physical contact or the use of cleaning agents. The underlying software plays a crucial role here: it continuously monitors the condition of the lens and automatically activates the compressed air valve as required to ensure optimum cleaning.